Quality Control Inspection Services

Part of Global Sourcing

China Sourcing International (CSI) offers exceptional quality control inspection services for businesses looking to source manufacturers overseas.

Inspection and quality control are critical processes to ensure that the supplies used to fulfill our clients’ orders are up to their standards. Our experienced staff members perform extensive inspections and quality control checks onsite. They know exactly what to look out for and always report defects immediately to minimize downtime and optimize productivity.

What are Quality Control Inspections Services?

From CAD drawings and 3D modeling through to logistics, regular inspections and quality control checks are put in place to verify that every part of the overseas manufacturing process is up to par.

Our sourcing and manufacturing management team in China are crucial for making sure products are to clients’ specifications before being shipped out to their customers.

We provide quality control checks throughout every stage of production. We inspect the entire pre, mid, and post manufacturing elements. You will have a team that stays with the products every step of the way to make sure that your goals are met when it comes to product specifications and the overall vision.

Our CSI Approach to Quality Control & Inspections?

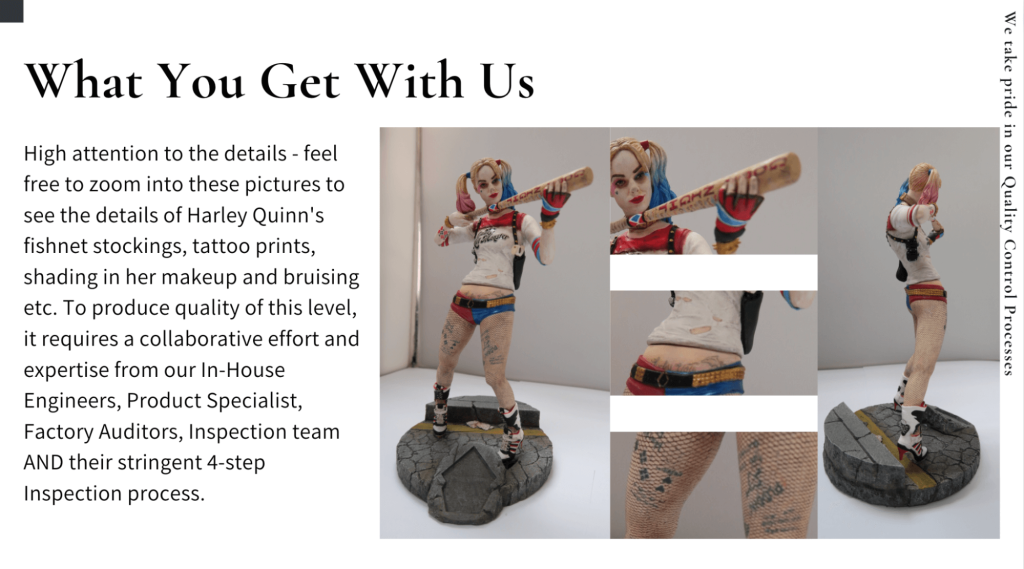

China Sourcing International hand-inspects all goods, materials, and supplies that arrive from our Chinese factories. From the moment we receive raw materials to the final stage of production, we look out for even the most minute flaws that could impact overall quality. As our client, you deserve the best and our quality control inspection team is here to deliver. Our acute attention to detail ensures that no stone is left unturned.

How do Inspections and Quality Control Differ?

This is a very common question since inspection and quality control are intricately interlinked.

Once a sample is ready, we have it sent to our Hong Kong office for a full inspection. Our team will determine if the sample meets the client’s specifications. We account for everything including height, weight, functionality, presentation, and many other factors. If there are any revisions that need to be made, we will go back and forth with the factory and the client until everything is satisfactory. This involves having the client sign off on the “golden sample,” which we then use as the quality control standard for all future production.

Call us at (628) 222-5510

Our Process

Regardless of the product we are manufacturing, China Sourcing International employs the following quality control inspection processes:

- Materials & Equipment – Prior to the actual inspection, we evaluate all raw materials and machinery to ensure functionality and quality.

- In-line production – At this stage, we inspect the first 10% of goods before approving further production. Anything that does not pass inspection is sent back for revision.

- Mid-line production – At this stage, we inspect 50% of goods before proceeding with production of the final 50%.

- Final Quality Control & Acceptable Quality Level (AQL) – This involves running a final inspection to verify the AQL on 100% of all manufactured goods.

Why Choose CSI Global Sourcing Services?

China Sourcing International is the global sourcing team you want on the ground to ensure that all supplies, materials, and end products turn out the way you want.

Along with factory audits, our team quickly and efficiently identifies issues related to quality and production and remedies them right away to avoid downtime, save on costs, and prevent disrupting your business. We make a commitment to our clients to never let product defects go into the final stages of production.

Your innovation is our reputation.

Work with China Sourcing International for an all-inclusive approach to fast, accurate, quality orders. Partnering with us means you will receive professionalism and quality execution every step of the way. We will make sure that your products are produced and delivered in pristine condition.

For more information about China Sourcing International’s inspection and quality control services, please contact us today.

To learn more about our CSI Quality Control Inspection Services

Call us at (628) 222-5510

Why Quality Control FAQs Matter

The quality control FAQs below cover real client concerns regarding:

- Consistency

- Preventive Action

- Inspection Integrity

- Standards Alignment

- Transparent Reporting

Sourcing Team Role

The sourcing team (4 team members) identifies and evaluates factories based on certifications, references, and initial quotes. They assess whether quotes are reasonable and pass them to our quoting team to send to clients. Call us at (628) 222-5510

Order Sourcing Process

Once the client confirms, the Engineering team audits the factory. After approval, the order is placed and followed through by the Operations Team. Final shipping documentation and vessel bookings are handled by the relevant team members. The team continues to oversee the shipment until it reaches the client.

The following FAQs are tailored to reflect what businesses typically ask sourcing agents and QC firms when sourcing from China and Hong Kong. Each answer highlights active, on‑the‑ground quality control measures that China Sourcing International (CSI) has in place and designed to protect product quality at every stage.

Quality Control FAQs

How do you ensure the “golden sample” used for quality control gets reproduced consistently?

The golden sample is reviewed by the engineering team. They document every detail (measurements, materials, finishing), and cross‑check future batches against it regularly on site.

Can you catch manufacturing issues before mass production begins?

Yes. We conduct a pre‑production inspection (PPI) that checks raw materials, equipment readiness, and initial setup to ensure the factory aligns with the specs before full-scale runs.

What do you examine during an on-site quality inspection of a factory?

The Engineer is responsible for all technical aspects when engaging with a factory. They inspect the factory’s production layout, machine calibration records, storage conditions for raw materials, and real-time adherence to SOPs. They also ask workers to walk through their process steps to uncover gaps between documentation and actual practice.

How often do you inspect during production?

An Inspector or the Engineer visits the factory at three stages:

- Early production (10%)

- Mid-production

- And final production

At the final stage, our Inspector conducts a thorough inspection.

How do you accurately assess a manufacturer’s production capacity?

Our team checks daily and weekly production logs, speaks with floor supervisors about shift flexibility, and examines how many orders are currently in queue. We verify if the factory runs single or multiple shifts and whether they own or rent their equipment.

Which quality control systems indicate a factory takes production quality seriously?

Factories that integrate ISO 9001 standards, deploy automated testing tools, and log inspection data digitally demonstrate high commitment to quality. We look for a dedicated internal audit team that reports independently to management.

What red flags do you watch for during a quality inspection?

The red flags we look for include inconsistencies in work instructions, uncalibrated testing tools, missing batch tracking systems, and incomplete inspection records. Any reluctance to show customer complaint logs will also raise concerns.

How do you verify that quality control staff are competent and unbiased?

We interview the QA team directly. Our team asks how they were trained, who reviews their reports, and whether they have authority to stop production. A quality team that answers to sales rather than management could signal compromised oversight.

What’s the most overlooked element of a factory’s quality program?

Ongoing employee training is often the most overlooked element of a quality program. Even with great systems, untrained operators make errors. CSI asks how often floor workers are re-certified, especially after process or equipment changes.

What happens if mid-production defects show up?

Our CSI team flags defects immediately, halts production if needed, and works with the factory to adjust processes and prevent further issues.

How do you define acceptable vs. critical defects?

We follow industry AQL standards. Minor defects (cosmetic), major defects (affect usability), and critical defects (safety or functionality fail), each level triggers specific corrective actions.

How do you handle inconsistent quality results from the same factory?

The engineer performs a root cause audit. They investigate operator turnover, seasonal staffing, changes in material sourcing, or breakdowns in calibration schedules. We also demand retraining or a revised quality plan before releasing further POs.

How do Chinese manufacturers typically handle rework or returns?

We request documentation showing rework processes, re-inspection criteria, and how returned goods are logged. Some factories might quietly repackage rejected items. Our team conducts spot checks to help deter this.

How do you evaluate how well a factory responds to quality issues?

CSI asks for corrective action reports from recent problems. We confirm that they identify root causes, not just symptoms, and verify implementation through dated evidence. Our team then follows up by reviewing similar recent orders for recurrence.

Do you verify packaging and labeling quality?

Yes. Our CSI team inspects packaging, labeling, and carton integrity at pre‑shipment to ensure they meet durability and regulatory standards.

How quickly do you deliver inspection reports?

CSI provides detailed inspection reports, complete with photos and measurements, within 24 to 48 hours after the visit .

Can you perform inspections for products made by our existing supplier?

Absolutely. The engineer can audit your current supplier’s site, monitor their production, and conduct pre‑shipment checks to reduce defects.

What quality standards do you enforce?

We customize QC protocols to your specs and enforce international standards like ISO 2859‑1 (AQL), CE, RoHS, FDA, or any sector‑specific benchmarks.

How do you identify whether quality issues stem from design or execution?

Our CSI team cross-checks your CAD drawings, samples, and Bill of Materials (BOM) with what’s being produced. If deviations occur despite clear specifications, execution is likely the issue. If not, we revisit your product design tolerances.

How do you maintain long-term quality consistency?

At CSI, we set up a supplier scorecard with KPIs like defect rate, lead time accuracy, and audit pass rates. We conduct quarterly quality reviews to keep audits objective.

What steps do you take during container loading?

During container loading, the inspection team creates a loading plan, a mapped layout showing how different product types are arranged in the container. We supervise the loading process, check container packing, weight distribution, and compliance with shipping standards to prevent damage or miscounts.

Please call us at (628) 222-5510 to learn more about our inspections and quality control services. Learn more about our factory audits!