Quality Control Inspection Services

Part of Global Sourcing

China Sourcing International (CSI) offers exceptional quality control inspection services for businesses looking to source manufacturers overseas.

Inspection and quality control are critical processes to ensure that the supplies used to fulfill our clients’ orders are up to their standards. Our experienced staff members perform extensive inspections and quality control checks onsite. They know exactly what to look out for and always report defects immediately to minimize downtime and optimize productivity.

What are Quality Control Inspections Services?

From CAD drawings and 3D modeling through to logistics, regular inspections and quality control checks are put in place to verify that every part of the overseas manufacturing process is up to par.

Our sourcing and manufacturing management team in China are crucial for making sure products are to clients’ specifications before being shipped out to their customers.

We provide quality control checks throughout every stage of production. We inspect the entire pre, mid, and post manufacturing elements. You will have a team that stays with the products every step of the way to make sure that your goals are met when it comes to product specifications and the overall vision.

Our CSI Approach to Quality Control & Inspections?

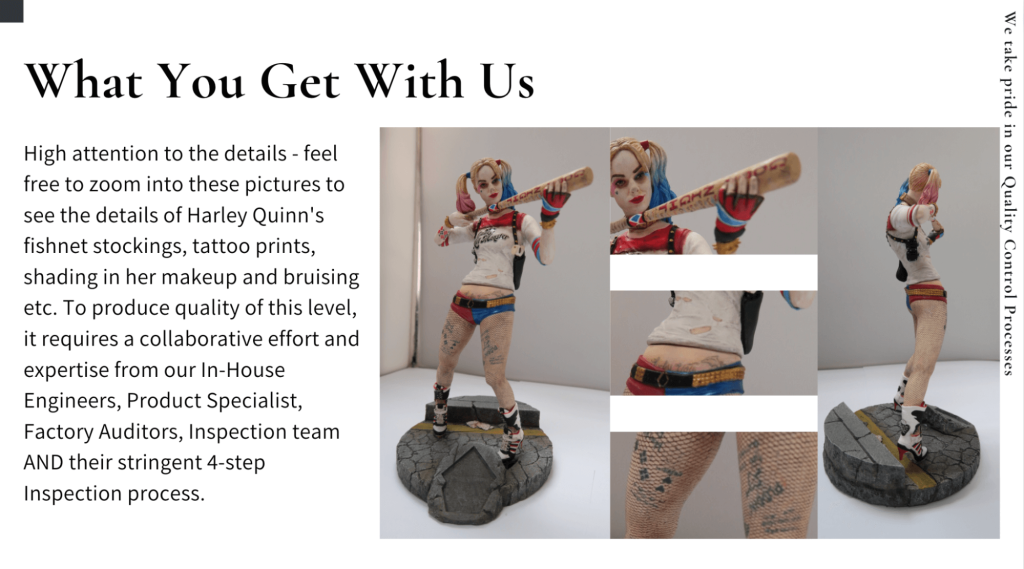

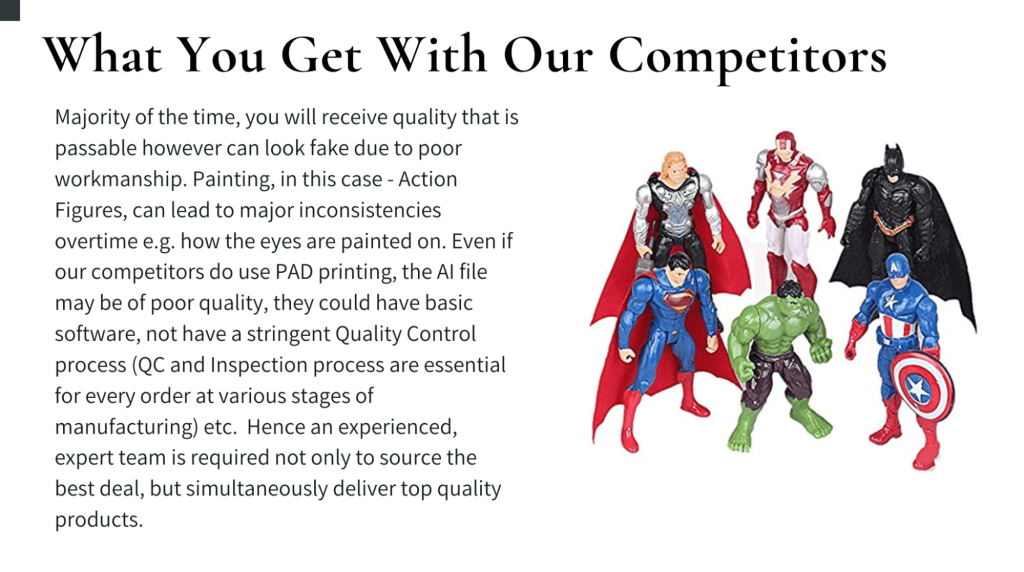

China Sourcing International hand-inspects all goods, materials, and supplies that arrive from our Chinese factories. From the moment we receive raw materials to the final stage of production, we look out for even the most minute flaws that could impact overall quality. As our client, you deserve the best and our quality control inspection team is here to deliver. Our acute attention to detail ensures that no stone is left unturned.

How do Inspections and Quality Control Differ?

This is a very common question since inspection and quality control are intricately interlinked.

Once a sample is ready, we have it sent to our Hong Kong office for a full inspection. Our team will determine if the sample meets the client’s specifications. We account for everything including height, weight, functionality, presentation, and many other factors. If there are any revisions that need to be made, we will go back and forth with the factory and the client until everything is satisfactory. This involves having the client sign off on the “golden sample,” which we then use as the quality control standard for all future production.

Our Process

Regardless of the product we are manufacturing, China Sourcing International employs the following quality control inspection processes:

- Materials & Equipment – Prior to the actual inspection, we evaluate all raw materials and machinery to ensure functionality and quality.

- In-line production – At this stage, we inspect the first 10% of goods before approving further production. Anything that does not pass inspection is sent back for revision.

- Mid-line production – At this stage, we inspect 50% of goods before proceeding with production of the final 50%.

- Final Quality Control & Acceptable Quality Level (AQL) – This involves running a final inspection to verify the AQL on 100% of all manufactured goods.

Why Choose CSI Global Sourcing Services?

China Sourcing International is the global sourcing team you want on the ground to ensure that all supplies, materials, and end products turn out the way you want.

Along with factory audits, our team quickly and efficiently identifies issues related to quality and production and remedies them right away to avoid downtime, save on costs, and prevent disrupting your business. We make a commitment to our clients to never let product defects go into the final stages of production.

Your innovation is our reputation.

Work with China Sourcing International for an all-inclusive approach to fast, accurate, quality orders. Partnering with us means you will receive professionalism and quality execution every step of the way. We will make sure that your products are produced and delivered in pristine condition.

For more information about China Sourcing International’s inspection and quality control services, please contact us today.

China Sourcing International (CSI) offers exceptional quality control inspection services for businesses looking to source manufacturers overseas.

Inspection and quality control are critical processes to ensure that the supplies used to fulfill our clients’ orders are up to their standards. Our experienced staff members perform extensive inspections and quality control checks onsite. They know exactly what to look out for and always report defects immediately to minimize downtime and optimize productivity.

To learn more about our CSI Quality Control Inspection Services

Call us at (888) 915-1060

Blogs

What Is A Sourcing Specialist & How to Select A Good One

Sourcing companies and agents are a dime a dozen but what is a sourcing specialist exactly and what is the best way to find the right one for your product or business? In this post, our experts at China Sourcing International (CSI) will discuss what a strategic sourcing specialist is, what they can do for…

The China Custom Manufacturing Process

Making a completely new custom product is referred to as original design manufacturing (ODM) and the China custom manufacturing process is first-rate. Embarking in ODM is the process of taking your product concept or idea and turning it into a finished product. ODM manufacturing is a complete process that involves: Here at China Sourcing International…

Unbeatable Pricing – Advantages of Manufacturing In China

For decades, companies in the United States have been discovering the advantages of manufacturing in China. They are often searching for not only less expensive ways to manufacture their products but also production efficiency and producing products that are top quality. Manufacturing in China does not show any signs of slowing; in fact, it’s only…